Cheers to beer! A pinch of physics, a dash of biology and a spoonful of chemistry all go into the brewing process.

Illustration by Jack Kaiser

Coming into summer, many of us enjoy a cold beer. But there’s more to these frothy confections of delight than meets the eye. Did you know that those flavours of chocolate, honey and bitterness all result from delicate tuning by brewing scientists? These hardy scientists carefully adjust pH levels, temperatures and enzymes to attain the perfect flavour balance. With a little malt, hops and yeast, brewers are able to transform water into that delicious beverage we call beer.

Beer has been brewed for at least seven thousand years. The oldest surviving recipe is a poem to the Sumerian goddess Ninkasi from around 1800BC. In those days, beer was made by soaking bread in water and letting it ferment with fruits, spices and honey. The resulting brew was very chunky and had to be drunk with a straw.

Obviously, beer has come a long way since then. Nowadays, expert brewers use precise knowledge of the chemical and biological processes involved in the making of beer, to craft flavoured beverages ranging from smoky chili chocolate stouts, to sour spritzy lemonade-style beers. Regardless of the type of beer, brewing follows some very specific and highly controlled steps. All of which are essential to making the unassuming beer we all enjoy.

Water is water, right?

The first ingredient in any beer is water. Water usually makes up 90–96% of the beer, the rest being mainly alcohol and compounds to flavour it. Believe it or not, but this high percentage of water actually has a large impact on the flavour of the beer, and has historically lead to certain types being predominantly brewed in specific areas.

Different types of beers can be brewed by changing the hardness of water. Hard water lends itself to stout style beers, like Guinness, while soft water creates light, hoppy beers such as pilsners. Divya Thakur/Flickr (CC BY-SA 2.0)

Dublin has particularly hard water, meaning it contains large amounts of bicarbonates and calcium which raise the pH of the water. To avoid harsh flavours in the beer, Dublin brewers rely on enzymes with very specific pH requirements of around 5.1–5.5. This requires roasted malts — which have an acidic effect on the brew – to lower the pH. These water conditions have resulted in the Irish stout style (such as Guinness) being developed there.

On the other hand, the Pilsen region in the Czech Republic has very soft water. This means it has a relatively low pH that is well suited to brewing, which has resulted in pale, hoppy beers, known as pilsners, being brewed there. Adding roasted malts to a brew done with Pilsen water would lower the pH too much, preventing the enzymes from doing their job.

A modern brewery often wants to be able to make all different types of beer, regardless of the water chemistry of their particular region. Brewers can do this by using very fine mesh filters with active carbon, basically stripping the water of anything that’s not H2O. This means that the brewer has to add additional salts, such as calcium sulfate and calcium chloride, back into the mix in order to obtain the ideal pH during the brewing process.

The mash, the malting mash

Once the water has been filtered, it needs to be the right temperature for the next step of the process: the mash. The mash is essentially a mixture of hot water and crushed malt (also known as grist), and is similar to a runny porridge. The purpose of the mash is to transform long chains of carbohydrates (starch) into fermentable sugars using enzymes naturally found in the grain. The brewer needs to take into account both the water chemistry and the amount of enzymes in each type of malt to make a recipe for a tasty beer.

Grist: kind of like porridge, this substance is a mixture of hot water and crushed malt. Emma Jane Hogbin Westby/Flickr (CC BY 2.0)

The temperature of this mixture of crushed malt and water causes specific enzymes to be activated. Two enzymes — β-amylase and α-amylase — are the most common, and are responsible for breaking down the large starch molecules into smaller bits of sugar. Each enzyme extracts a particular type of carbohydrate. β-amylase produces fermentable sugars (such as maltose), which are later turned into alcohol and CO2during fermentation. α-amylase produces unfermentable sugars (such as maltodextrins), which stay in the brew, adding body and fullness and bring a sweet, malty flavour to the beer.

β-amylase is activated at around 62–67ºC, and α-amylase around 71–72ºC. By carefully controlling the temperature of the mash, the brewer can determine the ratio between the two types of sugar, and thus the final amount of alcohol and malty flavours left in the beer.

Bring on the hops

Mashing usually takes around an hour to completely convert the starches in the malt into sugars. The brew (now called the wort) is ready to be boiled.

The first reason the wort is boiled, is to clarify the finished beer so that it looks nice in a glass. Along with carbohydrates, proteins are also extracted during the mash, and if these are not removed they will make the beer cloudy. By boiling the wort for about an hour, the proteins are broken down into smaller chunks, which aren’t soluble in beer, and are then easily removed at a later stage.

Secondly, and perhaps more importantly for the beer-drinker, the boil is where the hops are added. The hops used in brewing are the flowers, or more correctly the strobili, of the hop plant, Humulus lupulus. They grow on long vines, up to several metres in length, and require a specific climate of wet soil and dry air to flourish.

Hops contain a range of different chemical compounds that affect the flavour — the most important being the alpha and beta acids. Alpha acids act as a mild antibacterial agent, and add bitterness to the beer during the boil. Beta acids are essential oils, and act as aroma and flavour compounds that give the beer a distinctive taste and smell.

During the boil, the alpha and beta acids are extracted into the wort. Of the alpha acids, the most prevalent in hops is humulone. When heated up, it changes chemical structure into iso-humulone, which we beer lovers perceive as bitterness. Beta acids, on the other hand, have a tendency to evaporate over time, leaving less flavour and aroma behind. Because different types of hops have different combinations of alpha and beta acids, hop growers must have their produce analysed by a laboratory before the hops can be sold, so the brewer knows how they will affect the beer. In order to create a beer with an optimal combination of bitterness, flavour and aroma, the brewer must take into account the ratio between the two types of acid.

Effectively, this means that several batches of hops are added throughout the boil. The earliest is the bittering hops, which is usually boiled for around an hour with later additions of flavour and aroma hops, in order to obtain a balanced beer. The wort (our pre-fermented beer), is then cooled down to around 20ºC. Once oxygenated, it is then pumped into a fermenting vessel.

Now the wort is ready to be transformed from a sweet sugary liquid into delicious and alcoholic beer through the process beer-lovers all cherish: fermentation.

Converting sugar into alcohol

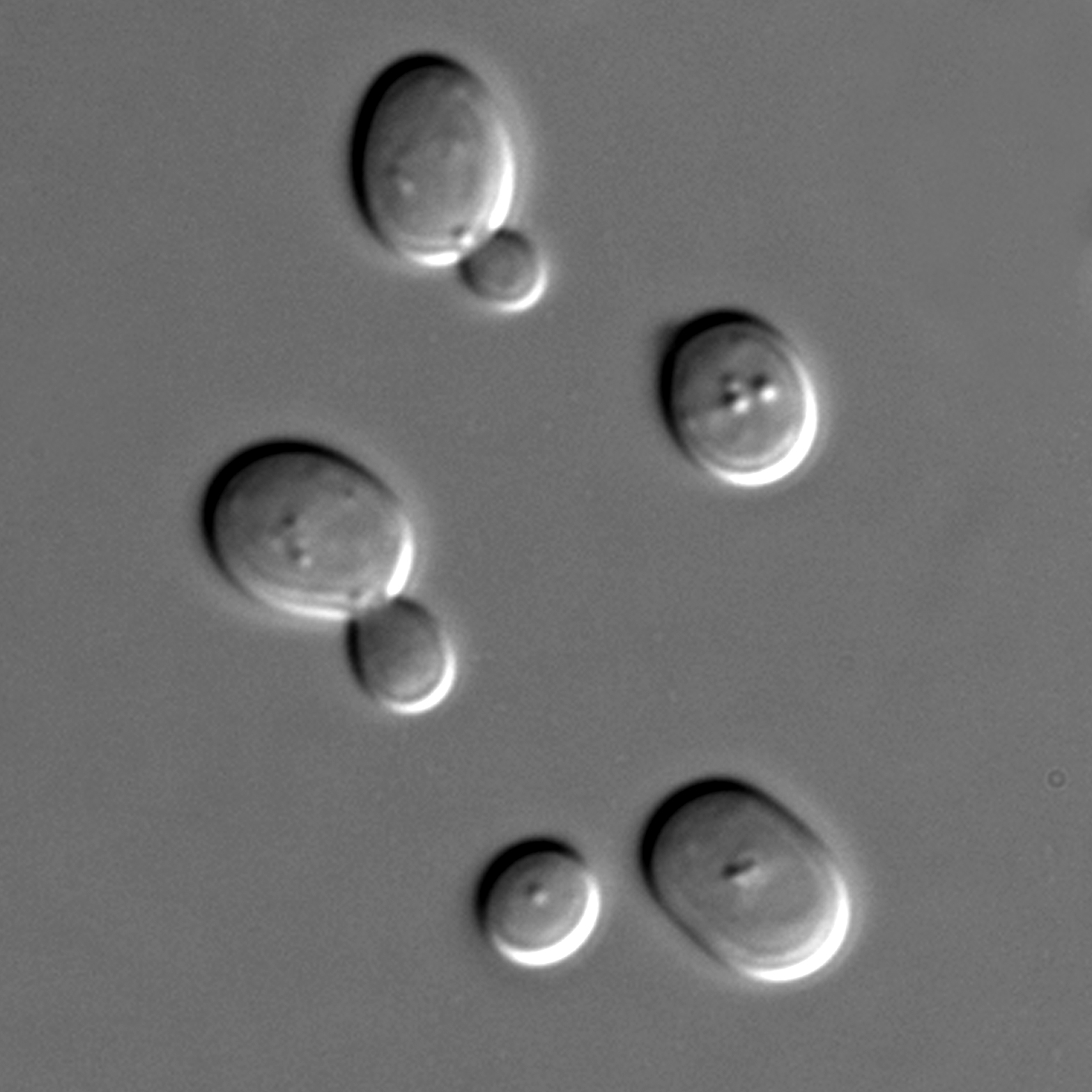

Enter the yeast. The superstar of the brewing process, yeast is responsible for converting the fermentable sugars into alcohol and CO2. Yeast is a type of fungus, with over a thousand different species that have been identified so far. Depending on who you ask, only one or two of these are used for brewing: the sugar fungus of beer (Saccharomyces cerevisiae) and Saccharomyces pastorianus, named in honour of Louis Pasteur. These are also known as ale and lager yeasts.

Within each species there are tens of different breeds, or strains, but all brewing yeast strains ferment sugar into alcohol and CO2. They differ mainly by which compounds they produce during fermentation, what temperature they ferment at, and how well they drop out of the beer after fermentation.

Fermentation of beer typically has three steps: primary fermentation, secondary fermentation and conditioning. The primary fermentation consists of an aerobic (with oxygen) and an anaerobic (without oxygen) phase. During the aerobic phase, the yeast cells eat the oxygen in the wort and multiply, creating a range of flavour compounds, such as esters (fruity), phenols (clovy), diacetyl (buttery), and sulfur containing compounds (eggy or gassy). The exact conditions of the primary fermentation determines which compounds are created during this process. A brewer can control parameters such as temperature, oxygen content, yeast content, and wort chemistry in order to coax the yeast into producing the right kind of flavour profile.

Once the oxygen has been consumed, the yeast moves on to anaerobic fermentation, in which the fermentable sugars are consumed and alcohol and CO2are produced. Different strains of yeast ferment optimally at different temperatures, with ale yeasts preferring temperatures between 17–24ºC, and lager yeasts preferring temperatures between 8–14ºC. The higher temperature for ales results in a faster fermentation, with more flavour compounds being produced. Lagers, however, take longer to ferment and have less flavour from the yeast.

Beer is a living thing.

Next, the beer is transferred into a different fermenter for secondary fermentation, in which the yeast particles begin to drop out of suspension, and some of the less desirable flavours are mellowed out.

Finally, the beer is cold conditioned at around 0ºC, allowing the majority of the yeast to drop out, clearing the beer and stabilising the flavours produced during fermentation.

Raise your glasses

After fermentation, the beer is finally ready to be packaged and consumed. Most of the CO2 produced during fermentation is released from the fermenters, otherwise the pressure would cause them to explode. But beer still needs to be carbonated. Carbonation is done either by forcing CO2 into the fermenter until the desired level of absorbed CO2 is obtained, or by bottle conditioning. Bottle conditioning is done by adding a small amount of additional sugar to the beer before bottling, allowing leftover yeast to ferment the sugar into CO2 and a small amount of alcohol. It can take a couple of weeks for this to happen, so most breweries prefer force carbonating their beers, which is really not as aggressive as it sounds.

Just four ingredients, and some meticulous science, are all that is needed to create such diverse flavours in the frothy concoction we call beer. FotoMediamatic/Flickr (CC BY-NC-ND 2.0)

After all of these long and very carefully controlled steps in the brewing process, the beer is now ready to be enjoyed. Cracking one open, you can hear the fizz of the CO2 escaping the pressure inside the bottle, and you can smell the essential oils and the esters from the hops and the yeast. Pouring it into a glass, you can see the colour caused by the malts, and tasting it, you experience the symphony that the brewer has created. The minerals in the water, the unfermented sugars, and the alcohol determine how the beer feels in your mouth. The iso-humulone, essential oils and esters activate sensors on your tongue, while the CO2 carries flavour compounds into your nose triggering a myriad of flavour signals in your brain. For a fraction of a second, you subconsciously process all of these impressions before they turn into a fully formed sensory painting for you to enjoy.

Over the course of a few weeks, brewers are able to transform four basic ingredients — water, malt, hops and yeast — into delicious beer. It requires a deep understanding of chemistry, biology, and even a bit of physics. Without this crucial knowledge, or the skill and craft of expert brewers around the world, we would still be drinking chunky beer through a straw. Thankfully that’s not the case, so cheers!